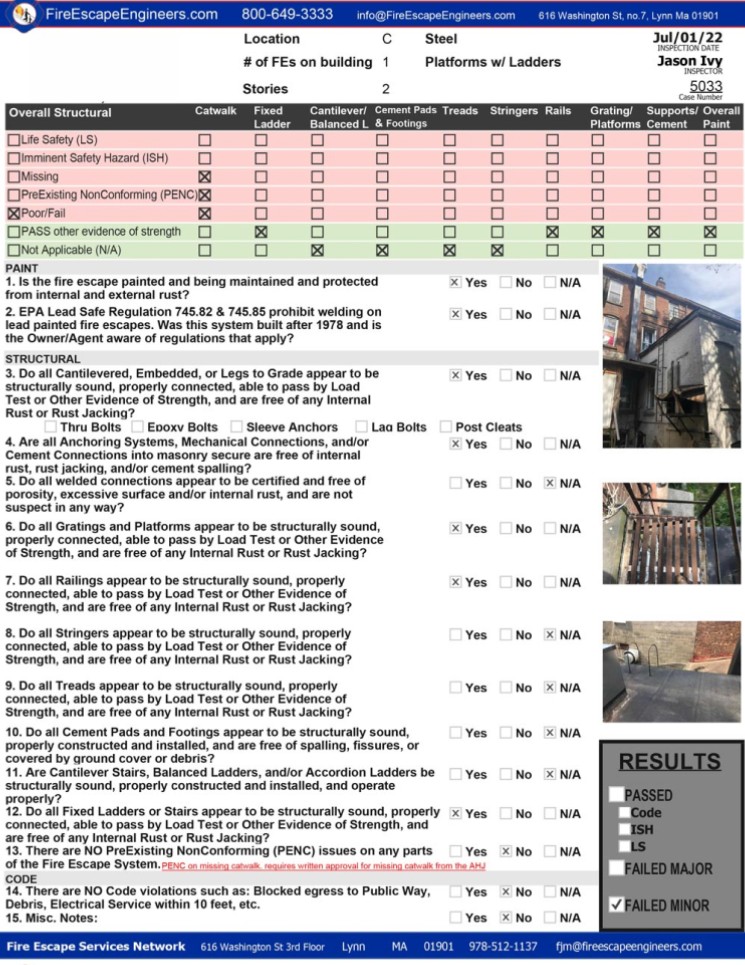

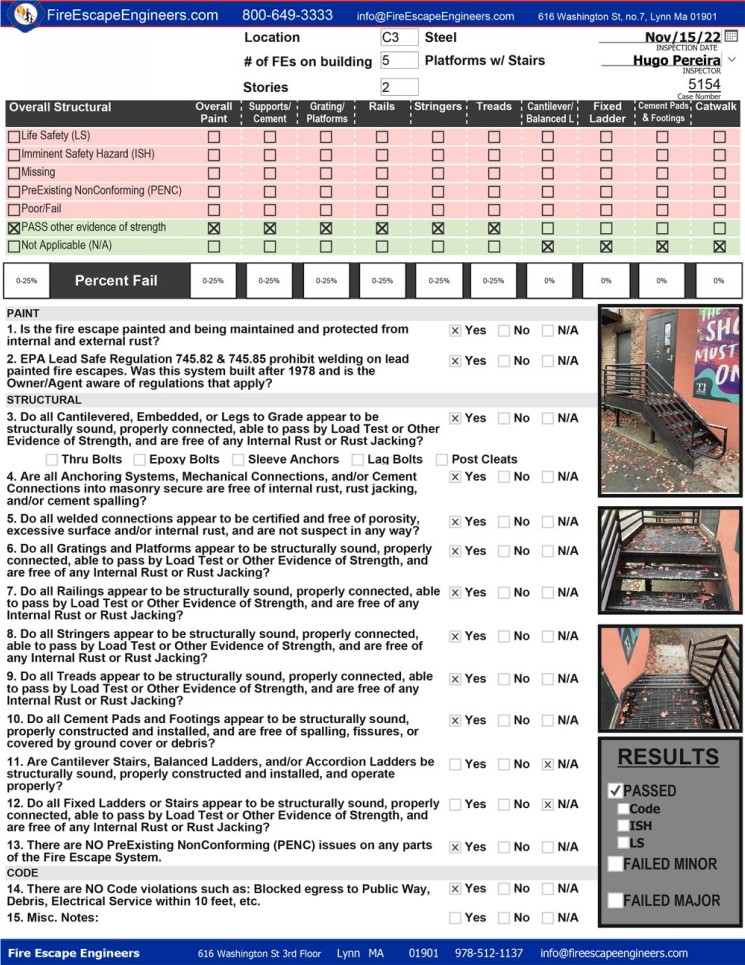

During the inspection process, professionals will conduct a visual walk-through examination of all connections in the fire escape system. Videos and photos will be taken help to identify any distressed condition and deficiency to review with the owner, agent, or AHJ. This includes checking for rust, wear and tear, and other signs of damage that may impact the structural integrity of the fire escape. The inspection also includes verifying that paint is properly maintained. Moreover, the fire escape must meet industry standards in the year it was constructed. Any preexisting non-conforming issues will be reviewed by the AHJ if required.

Once the inspection is complete, a Pass/Fail Certificate will be submitted to the AHJ, indicating either a successful certification or a failed inspection. If the inspection fails, a subsequent (3) remediation technical report must be submitted by a qualified professional approved by the AHJ.

As per the local city official, it is mandatory to conduct a critical examination of fire escape systems by a Registered Design Professional or Other . This examination should thoroughly inspect the fire escape system and ensure that all connections, hardware, and supports are free of rust and in good condition, while also providing photo reports with details of any code violations. The examination should consist of a 25-point checklist to verify compliance with the safety codes.

If the fire escape passes the examination, a fire escape certification and tag must be submitted to the AHJ. The certification can be achieved through Load Test, Other Evidence of Strength in Lieu of Load Test, or an Opinion Affidavit with Disclaimer of Liability.

It is essential to comply with these requirements to ensure the safety of the building occupants and avoid any legal complications. Please take prompt action to conduct the necessary examinations and submit the certifications to the AHJ.

A Technical Remediation Report for a fire escape system is a comprehensive assessment prepared by an engineer that outlines the necessary repairs to ensure its safety and structural integrity. It covers all components, including treads, rails, supports, ladders, counterbalanced stairs, connections, bolts, and rivets, and describes the system's current condition. Specific repair plans are created for each component, outlining any necessary replacements, reinforcements, or modifications.

To protect against corrosion and environmental factors, the report also provides specific requirements for sealant and paint, including product recommendations, application techniques, and maintenance schedules. The engineer oversees the repair process through 3-5 onsite visits, confirming the use of the correct materials and techniques to ensure structural integrity and safety.

The first visit reviews the remediation plan with the contractor, materials, and schedule. The second visit confirms ongoing work meets required standards. The third visit ensures the remediation work is complete, and the system functions correctly. Additional visits are scheduled as necessary to address concerns. Upon completion, the Design Professional or Other acceptable of record must verify that all remediation described in the report have been completed, thereby establishing Other Evidence of Strength in Lieu of Load Test. Otherwise, a Load Test or Opinion Affidavit with Disclaimer of Liability must be considered.

Load tests are an important part of the certification process for fire escapes, which has been in place since 1927. The Certification process also includes another path called Other Evidence of Strength. An AHJ has the power to require load testing of a fire escape system at any time. In some cities, a load test is mandatory every five years for Certification.

Before conducting a load test, a safety check is done to ensure that all components of the fire escape are structurally sound. During a load test, the structural components of the fire escape are put under a 100 pounds per square foot stress test for at least a half hour, and any deflection is measured. (1) If no deficiencies are found (PASS) a Certification is submitted. If any components are found to be suspect (FAIL), they must be restored before the load test can be conducted. (2) A Deficiency Technical Report is generated listing the suspect components that could not load tested at that time. Once all deficiencies are correct a Certification is submitted to the AHJ.

Alternatively, a full restoration of the fire escape can be done to avoid load testing. This is considered Other Evidence of Strength by the AHJ and guarantees structural integrity for 25 years. However, a corrosion protection plan must be maintained, which involves sealing and painting the fire escape every 5-7 years.

Exterior elevated elements in buildings include load-bearing components, like balconies, decks, porches, elevated walkways and ramps or any structure that extends beyond the walls of a building and has a walking surface elevated more than six feet above the ground, must be inspected and maintained. These structures can be made from wood, metal, concrete and composite materials. Local, state and national codes related to these exterior elevated elements differ in how often inspection reports are required to be submitted to the AHJ. Please check with your AHJ for your specific requirements or call us and we can tell you.

When buildings undergo a change of use, it is important to assess the existing fire protection and life safety systems to ensure that they meet the new occupancy requirements. A change of use can include converting a commercial space to a residential one, changing a storage area into a manufacturing plant, or repurposing an office space into a healthcare facility. In these scenarios, it is essential to conduct a comprehensive fire protection and life safety evaluation to identify any deficiencies or necessary upgrades.

The evaluation process should start with a thorough analysis of the building's layout, occupant load, and fire protection systems. This includes assessing the fire suppression, detection, and alarm systems, as well as the means of egress, fire-rated walls, and doors. The assessment should also consider any new requirements that may apply to the new occupancy classification, such as the installation of a sprinkler system or the addition of fire-resistant materials.

By conducting a comprehensive evaluation, building owners or managers can identify any potential fire hazards and take steps to mitigate them before they become a problem. This can help ensure that the building is safe and compliant with all necessary fire protection and life safety codes and standards. This evaluation process can identify any deficiencies or necessary upgrades and help ensure that the building is safe and compliant with all necessary codes and standards.

Any and all connections with INTERNAL rust (bolted, riveted and or welded) will be restored: opened, scraped clean, spot primed, encapsulated with 35-50-year paintable silicone, and re-bolted with appropriate size and grade, identified or not, specified in the Technical Repair Report. All deteriorated material will be reinforced or replaced as identified. All wall connections (thru-bolt or cement) must be verified otherwise restored, re-cemented 4 to 6 inches maximum around connection, or replaced. Full Restoration of ALL major connections will result in Other Evidence of Strength, in Lieu of Load Test (NFPA LIFE SAFETY CODE 1017.2.8.6.2 The AHJ shall approve any fire escape by Load Test or other evidence of strength (Certification).

Unless otherwise noted this is a Certification, in Lieu of Load Test. (No Disclaimer of Liability). Guaranteed acceptance by all AHJ and compliance with all Codes IFC IBC NFPA OSHA. AHJ may still require a load test.

All EXTERNAL SURFACE rust and corrosion and restored components will be scraped, wire brushed, spot primed and the entire structure will be painted (1 coat) as per the Technical Repair Report specifications. EPA guidelines for LEAD Paint apply.

Load tests have been in the code since 1927. To address your liability concerns, we want to emphasize the importance of load tests on fire escapes structures that are 75 to 125 years old that have never been maintained in obtaining certification. It is one of the paths to certification, the other is Other Evidence of Strength. The Design Professional/Other of record or the AHJ at any time can require the load testing of a system. Load tests can be avoided by a full restoration, which is considered Other Evidence of Strength by the AHJ which has been proven to the AHJ.

Load testing a fire escape involves putting all the structural components of the egress under a 100 pounds per square foot stress test and measuring any deflection after at least a half hour and any deflection is measured.

Every connection in the system is taken apart.

Each component is cleaned of rust and corrosion.

Parts that have material loss are either sistered or replaced with new material.

All supports and all footings repacked and or sealed.

All bolts replaced with new bolts.

All connections sealed with paintable 50 year silicone caulking.

The system is primed and fully painted following EPA Lead Paint Guidelines.

Restoration “restores” the structural integrity such that it is guaranteed to pass the next three certifications, that is 15 years at least. One caveat is the system must be fully painted every five to seven years. A corrosion protection plan is part of the guarantee.

Only the connections with excessive rust and/or material loss are cleaned, reinforced if necessary, then bolted with new bolts.

All other connections are load or dynamic stress tested.

The system is cleaned of all surface rust, primed and then a full top coat of paint following EPA Lead Paint Guidelines.

A 10 year structural guarantee is issued only on current work performed.

The Spot Restoration can be credited towards a Full Restoration if the work is scheduled within 5 years of Spot Restoration completion. Price will be adjusted for inflation, labor rates at that time and some restrictions may apply.

Only distressed components with material loss, very poor welds and/or broken connections will be reinforced or repaired as needed.

All other connections are load or dynamic stress tested.

Spot Paint includes scraping and priming loose or peeling paint, surface rust, and repaired areas.

A spot top-coat of paint is applied to repair areas following EPA Lead guidelines.

The system is certified by load/dynamic stress test and there is no guarantee it will pass certification in five years.

As an owner or agent, it is important to know that the AHJ requires a paint vendor, who is an EPA Certified Renovator if the fire escape has lead paint, to follow EPA guidelines for lead paint when doing all painting work. Fire escapes built before 1978 are assumed to have lead paint, unless certified by a licensed lead inspector as no lead or low lead. The guidelines require notifying building occupants with signage, taking precautions when collecting lead paint chips, and avoiding sandblasting or power-assisted scraping without full fire escape encapsulation.

All major connections should be sealed with 35-50 year paintable silicone to prevent water intrusion, and fire escapes should be spot primed and painted every 3-5 years and fully painted every 5-10 years, or as needed, and/or ordered by the AHJ. Oil based paint is preferred for durability and adherence properties. However, water base paint can be used. In either case, all bare surfaces should be primed and all fully rusted systems are recommended to have a carbonizing primer applied to maximize the protection from new rust growth.

Load tests have been in the code since 1927. To address your liability concerns, we want to emphasize the importance of load tests on fire escapes structures that are 75 to 125 years old that have never been maintained in obtaining certification. It is one of the paths to certification, the other is Other Evidence of Strength. The Design Professional/Other of record or the AHJ at any time can require the load testing of a system. Load tests can be avoided by a full restoration, which is considered Other Evidence of Strength by the AHJ which has been proven to the AHJ.

Load testing a fire escape involves putting all the structural components of the egress under a 100 pounds per square foot stress test and measuring any deflection after at least a half hour and any deflection is measured.